Volvo Oil Cooler Problems – Causes, Symptoms, and Repair Solutions

Introduction – Why the Oil Cooler Matters in Volvo Trucks

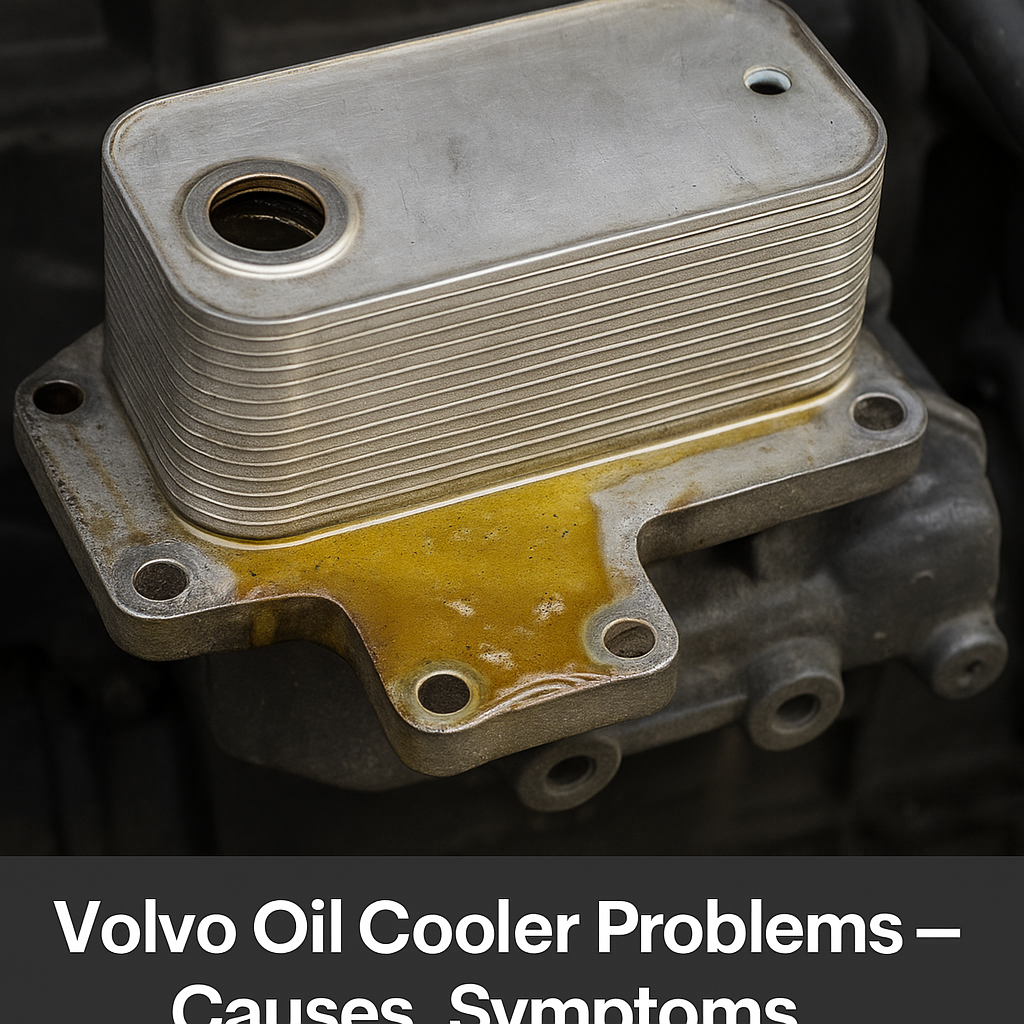

The oil cooler in Volvo heavy-duty engines like the D12, D13, and D16 plays a critical role in keeping oil temperatures within safe limits. By transferring excess heat from the engine oil to the coolant or outside air, the oil cooler ensures proper lubrication and prevents oil breakdown under extreme load conditions.

When the Volvo oil cooler fails, the consequences can be severe: coolant contamination, overheating, loss of lubrication, and even catastrophic engine damage. For fleets and independent truck owners, understanding the causes, symptoms, and repair solutions for Volvo oil cooler problems is essential for keeping trucks reliable and minimizing downtime.

What Does the Volvo Oil Cooler Do?

-

Maintains oil at optimal temperature for lubrication.

-

Prevents engine overheating by transferring excess heat.

-

Protects seals, bearings, pistons, and turbochargers from oil-related damage.

-

Works in tandem with the cooling system to keep the engine balanced.

Without a functioning oil cooler, both oil and coolant can become contaminated, leading to accelerated wear and costly repairs.

Common Causes of Volvo Oil Cooler Problems

-

Coolant Contamination

-

Internal leaks allow coolant and oil to mix.

-

Results in “milky” oil and reduced lubrication.

-

-

Corrosion and Wear

-

Long-term exposure to poor-quality coolant or lack of maintenance causes corrosion of the cooler core.

-

-

Blocked Passages

-

Soot, sludge, or metal debris restricts oil or coolant flow.

-

-

Thermal Stress

-

Repeated heating and cooling cycles weaken the oil cooler over time.

-

-

Improper Maintenance

-

Ignoring oil and coolant service intervals increases risk of failure.

-

Symptoms of Volvo Oil Cooler Failure

-

Milky Oil – Coolant mixing with oil, visible on dipstick or filler cap.

-

Coolant Contamination – Oil film present in coolant reservoir.

-

Engine Overheating – Oil cooler unable to regulate temperature.

-

Loss of Oil Pressure – Blocked cooler passages reduce flow.

-

Exhaust Smoke (White/Blue) – Oil or coolant entering combustion chamber.

-

Check Engine Light – Fault codes for oil pressure or coolant temp imbalance.

Troubleshooting Volvo Oil Cooler Problems

| Symptom | Likely Cause | Recommended Fix |

|---|---|---|

| Milky oil | Oil and coolant mixing | Replace oil cooler, flush fluids |

| Oil film in coolant reservoir | Internal cooler leak | Pressure test & replace cooler |

| Engine overheating | Blocked cooler passages | Clean or replace cooler |

| Loss of oil pressure | Restricted flow | Replace cooler & check oil pump |

| White exhaust smoke | Coolant in combustion | Inspect oil cooler + head gasket |

Diagnosing Volvo Oil Cooler Issues – Step-by-Step

-

Visual Inspection – Check dipstick, oil filler cap, and coolant reservoir.

-

Pressure Test Cooling System – Look for pressure loss from oil cooler leaks.

-

Oil Analysis – Detects coolant contamination in oil.

-

Infrared Thermometer Test – Measure cooler’s temperature differential.

-

Remove and Bench Test Oil Cooler – Confirms internal leaks.

Repair and Replacement Solutions

-

Coolant Flush & Oil Change – Required whenever oil and coolant mix.

-

Cleaning Oil Cooler – Only possible if blockage is minor.

-

Oil Cooler Replacement – Most common repair, especially for cracked or corroded units.

-

Head Gasket Inspection – Ensure coolant contamination isn’t from head gasket failure.

Cost of Volvo Oil Cooler Replacement

-

Part cost: $600–$1,200 (OEM or high-quality aftermarket).

-

Labor cost: $700–$1,500.

-

Total: $1,300–$2,700.

Preventing Volvo Oil Cooler Problems

-

Replace coolant at Volvo-recommended intervals.

-

Use only Volvo-approved coolant and engine oil.

-

Inspect cooling and oil systems during every service.

-

Perform regular oil analysis to catch contamination early.

-

Avoid extended overheating events, which weaken cooler seals.

Real-World Case Study – Volvo D13 Oil Cooler Failure

A fleet of 2016 Volvo VNL trucks with D13 engines began showing milky oil samples and frequent overheating. Diagnostics revealed multiple oil cooler failures due to corrosion from poor coolant quality.

-

Fix: Replaced oil coolers with OEM units, flushed coolant and oil systems, and introduced strict coolant maintenance intervals.

-

Result: Contamination issues dropped by 95%, and downtime decreased significantly.

FAQs

What are the symptoms of Volvo oil cooler failure?

How do I know if my Volvo D13 oil cooler is bad?

Can a bad oil cooler cause engine failure?

How much does Volvo oil cooler replacement cost?

Can I drive with a leaking oil cooler?

How often should I replace Volvo coolant to protect the oil cooler?

What causes Volvo oil cooler leaks?

Can I clean a Volvo oil cooler instead of replacing it?

Does oil cooler failure affect turbochargers?

Is OEM better than aftermarket for Volvo oil coolers?

Internal Links

Volvo Head Gasket Failure – Symptoms, Causes, and Repair Guide

Volvo Turbo Actuator Problems – Symptoms, Diagnosis, and Repair Solutions

Volvo EGR Cooler Problems – Causes, Symptoms, and Fixes

Volvo Injector Problems – Symptoms, Causes, and Repair Solutions

Volvo Engine Overheating Issues – Causes, Diagnosis, and Fixes

Conclusion – Protecting Your Volvo Engine from Oil Cooler Failures

A failing oil cooler can silently damage your Volvo engine by allowing coolant and oil to mix or by restricting vital oil flow. Catching early symptoms like milky oil, overheating, or coolant contamination is key to avoiding catastrophic damage.

By following preventative maintenance practices, using OEM-quality replacement parts, and scheduling regular inspections, fleets and owner-operators can dramatically reduce the risk of Volvo oil cooler problems and keep trucks on the road.

Contact Information

📧 Email: info@volvokits.com

📞 Phone: 786-814-1410

🌐 Website: https://www.volvokits.com